Pellet Extruders

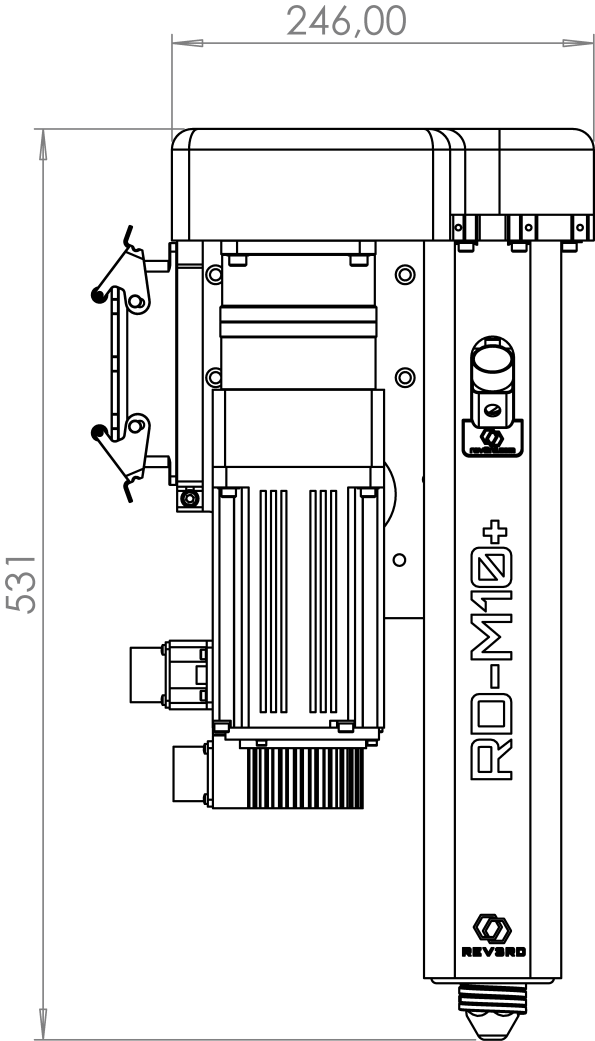

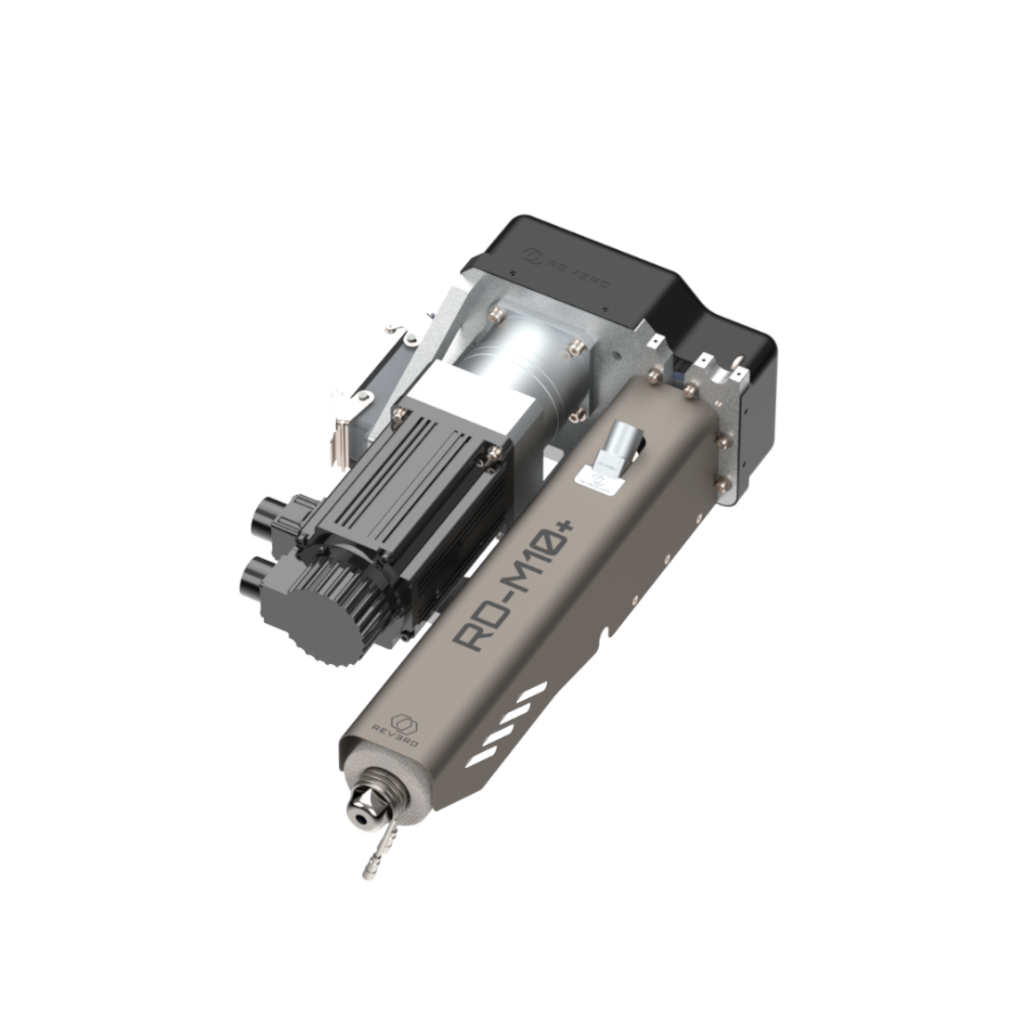

RD-M10+NEXT-GEN PELLET EXTRUDER

The RD-M10+ is a next-generation high-flow plastic and light weight pellet extruder. It was designed to 3D print components as fast and cost-effective as possible. It can be combined with robotic or machine systems. RD-M10+ is able to output up to 12kg of material per hour.

Available for order

Water Cooling - Hot Environment Ready

The RD-M10+ is able to operate in any environmental condition. The water-cooling loop keeps the whole system (motor, screw shank, reducer and feeding zone) at a constant temperature.

Tri-zone Heating Screw Control

The triple heat zone design helps to keep the polymer at a constant temperature. The feeding section receives cold pellets and generates more heat to melt them. Then, the compression zone stabilizes the polymer at a precise temperature ensuring the plastification process (all the solid pellets turn into a molten status). Finally, the metering heater ensures an even flow.

Multiple Nozzle Size

RD-M10+ can be used with large nozzles from 2.5mm up to 10.0mm. They can also be customized.

High Throughput Light weight

RD-M10+ can output up to 12 kg/h. It is our highest output solution in the light-weight category ( < 10kg ) and the fastest portable pellet extruder on the market.

Customized Extrusion Screw

The bimetallic customized screw design is optimized for high-resolution 3D printing. Two tapered bearings, which support the screw, allow a low friction rotation, a bore centering of the screw in the barrel and can handle the whole high axial force required to extrude in high-speed and pressure conditions.

Melting Zone Sensor

The temperature sensors are placed only 0,5 mm away from the molten polymer. Readings are reliable and accurate.

Precise Temperature Control

The three K-type thermocouple sensors are class 1, high precision sensors. The circuit has been designed to use the best resolution between 20°C and 500°C.

Powerful SERVO Motor

The powerful Geared SERVO MOTOR can handle high flow without any strain. To maximize RD-M10+ extruder’s compatibility, the motor driver can accept 0-10V signals as well as step and direction signals.

Breaker

The fast speed of RD-M10+ is managed by a breaker. Like the faucet filter does with the water, the breaker aligns the output flow in order to avoid the spiral effect created by high-speed.

Uniform Heating

The spiral heaters wrap the whole heated barrel and ensure uniform temperature along the whole length end of the extruder.

Insulation Blanket

A special insulation blanket is used to coat the Cylinder, in order to keep the heat inside and save the energy required to reach the temperature setpoints.

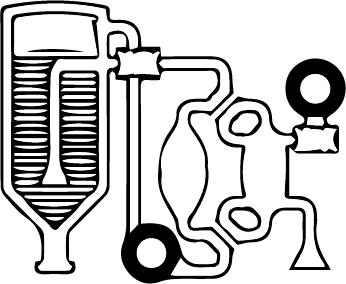

Automatic Feeding System

RD-M10+ can come with an optional venturi feeding system which detects the pellets level and auto-charges the extruder. Pellets can be delivered from a bulk source or directly from a dryer.

Dryer

This system is necessary to remove moisture and avoid faulty parts when printing hygroscopic compounds. RD-M10 can come with different dryer capacity: 12, 25 or 50 kg per hour.

Watt max heating power

grams max flow

- Throughput 12 Kg/h (tested with PETG)

- Energy saving with our insulation system

Technical Specifications

RD-M10+

| PARAMETER | VALUE |

| Weight | ~18 kg |

| Screw diameter | 16 mm |

| Max temperature | 500 °C |

| Max environment temperature | 60 °C |

| Available nozzle sizes | from 2.5 to 10.0 mm |

| Max flow | 7 – 12 kg/h |

| L/D ratio | 20D |

| Heating power | 1 – 2 kW |

| Compression ratio | 2.5 |

| Cooling | water cooling jacket |

| Planetary gearbox ratio | 10 – 20 |

| Belt trasmission ratio | From 0.5 up to 2 |